![]()

Need assistance with selecting the correct solution to meet your specific requirements?

![]()

To see the Air Treatment Solutions Brochure

MAINTENANCE

Replace the filter element at least every 12 months or follow the instructions for the specific filter element. For detailed maintenance instructions, please follow the installation and operating manual.

MATERIALS

Housing Material:

- Carbon steel (P250GH)

Fittings, Screws:

- Stainless steel (1.4404)

Sealing:

- NBR with PTFE backup ring

Lubricant:

- Weicon AL-F (Code 265500)

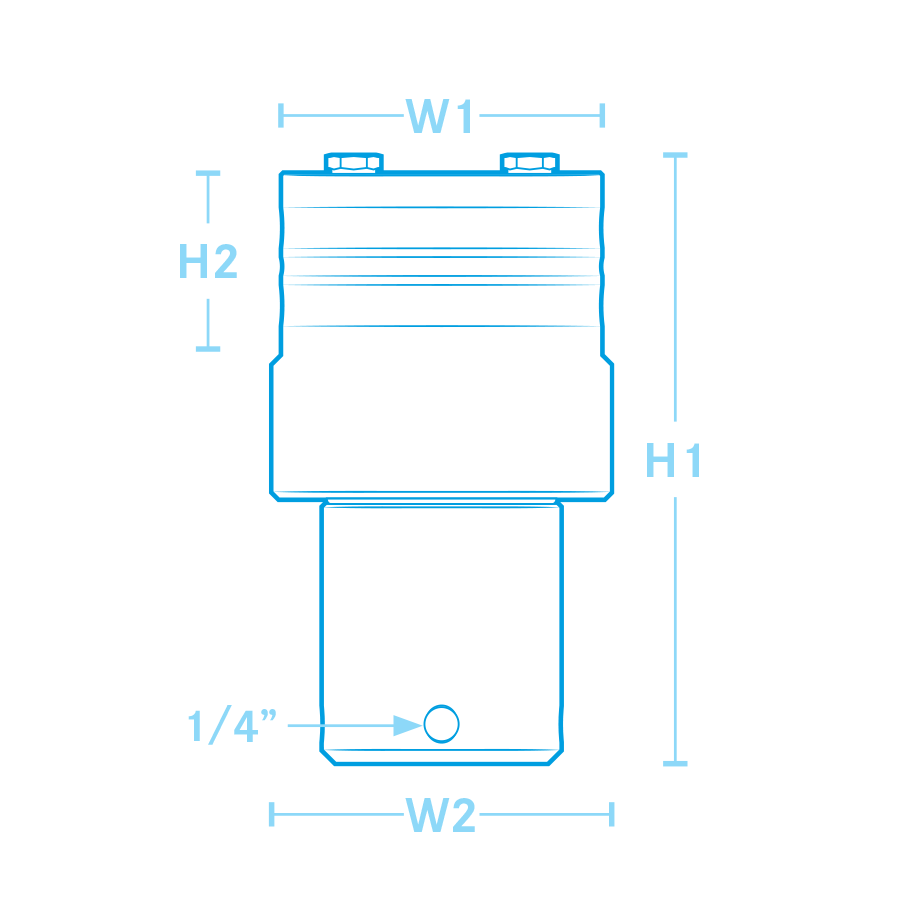

BAUER PX FILTER FOOTPRINT

PX05:

DIMENSIONS H1 X W1 X H2 X W2 inches (mm)

- 7.2” x 3.9” x 1.2” x 4” (183.5mm x 98mm x 31mm x 104mm)

PX07:

DIMENSIONS H1 X W1 X H2 X W2 inches (mm)

- 9” x 4.6” x 1.7” x 5” (230mm x 118mm x 44mm x 129mm)

PX10:

DIMENSIONS H1 X W1 X H2 X W2 inches (mm)

- 10” x 4.6” x 1.7” x 5” (254mm x 118mm x 44mm x 129mm)

TECHNICAL DATA

| Model | Pipe Size | Filter Element | Flow Capacity | Volume | |

| inches | scfm | m3/h | liters | ||

| PX05 | 3/8 | F05 | 494.4 | 840 | 0.20 |

| PX07 | 1/2 | F07 | 918 | 1560 | 0.40 |

| PX10 | 3/4 | F10 | 1380 | 2340 | 0.48 |

Flow capacity at 100 – 420 bar(g), 20°C. Standard is BSP pipe connection, other pipe connection on request.

FILTER ELEMENT TYPES

| Filter Designation | Filter Type | Filter Material | ISO 8573:20 10 class | Residual Oil Content* | Particle Retention | Operating Temperature Range | ||

| Particle | Water | Total Oil | Nominal | |||||

| P | Prefilter | Borosilicate Micro Fibers | 3 | - | - | - | 99.9999% (1μm) | +1.5...+80°C |

| M | Microfilter | Borosilicate Micro Fibers | 2 | - | - | <0.1 mg/m3* | 99.9999% (1μm) | +1.5...+80°C |

| F | Finefilter | Borosilicate Micro Fibers | 1 | - | - | <0.01 mg/m3* | 99.9999% (1μm) | +1.5...+80°C |

| A | Activated Carbon | Borosilicate Micro Fibers, activated Carbon | 1 | - | 1** | <0.0005 mg/m3* | - | +1.5...+45°C |

Filter element types

*Elements M and F do not remove oil vapor; values, therefore, are only valid for droplets and aerosols.

**Filter element A with activated carbon: For removing small residual amounts of oil vapor, e.g. downstream SECCANT-A or P filter (with activated carbon cartridge). Max. input concentration 0.1 mg/m3 oil vapor and max. 0.01 mg/m3 oil droplets and oil aerosols. It should not be used if the gas is saturated with oil vapor. Regular replacement of the element is necessary after 6 months at the latest. Use a separate activated carbon filter for oil vapor removal from normally saturated gases.

SYSTEM AIR QUALITY SPECIFICATIONS AT SYSTEM DISCHARGE

| ISO8573-1:2010 Class | Solid Particulate | Water | Oil | ||||

| Maximum Number of Particles per m3 | Mass Concentration | Vapor Pressure Dewpoint | Liquid | Total Oil (aerosol liquid and vapor) | |||

| 0.1-0.5 micron | 0.5-1 micron | 1-5 micron | mg/m3 | g/m3 | mg/m3 | ||

| As specified by the equipment user or supplier and more stringent than Class 1 | |||||||

| 0 |

≤ 20.000 |

≤ 400 | ≤ 10 | - | ≤ -70 | - | 0.01 |

| 1 |

≤ 400.00 |

≤ 6.00 | ≤ 100 | - | ≤ -40 | - | 0.1 |

| 2 | - | ≤ 90.00 | ≤ 1.000 | - | ≤ -20 | - | 1 |

| 3 | - | - | ≤ 10.000 | - | ≤ +3 | - | 5 |

| 4 | - | - | ≤ 100.000 | - | ≤ +7 | - | - |

| 5 | - | - | - | - | ≤ +10 | - | - |

| 6 | - | - | - | ≤ 5 | - | - | - |

| 7 | - | - | - | 5-10 | - | ≤ .05 | - |

| 8 | - | - | - | - | - | .05-5 | - |

| 9 | - | - | - | - | - | 5-10 | - |

| X | - | - | - | >10 | - | >10 | >10 |