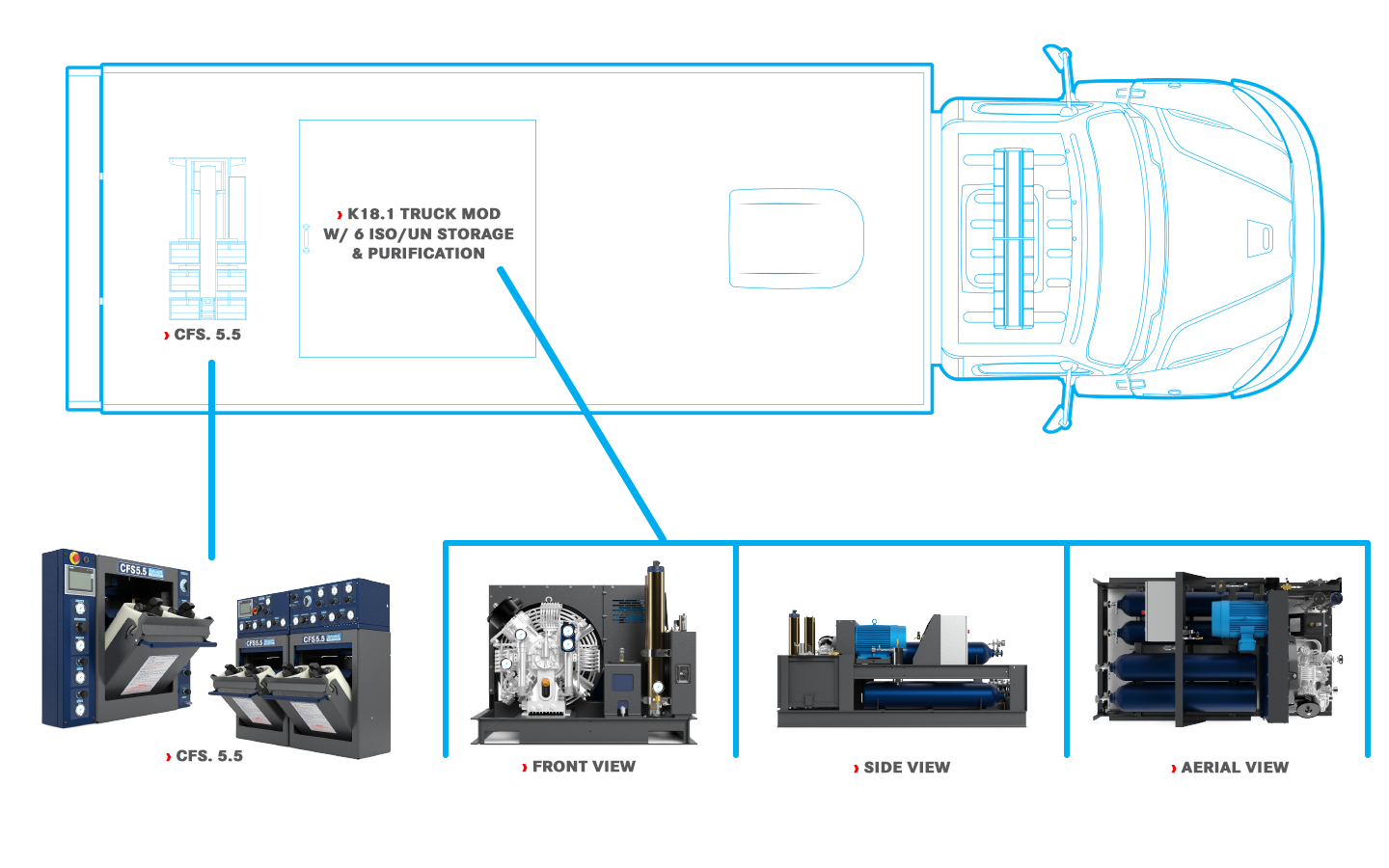

MOBILE PACKAGES

When your department requires the need for a mobile breathing air truck, look no further than BAUER. For 75 years, BAUER has been the industry leader in high-pressure breathing air compressor systems. We start with critical components designed, engineered, and manufactured in our factories. Our sales and engineering staff work closely with your truck manufacturer of choice to ensure the entire system meets your department's critical needs. Your closest factory-authorized BAUER partner is brought into the equation to maximize customer satisfaction and support with the product after the truck has been delivered to you.

![]()

Need assistance with selecting the correct solution to meet your specific requirements?

STANDARD SCOPE OF SUPPLY FOR COMPRESSOR SYSTEMS

- Skid-mounted BAUER multi-stage air-cooled compressor

- BAUER breathing air purification system with B-SECURUS electronic moisture monitoring system.

- BAUER B-drain automatic condensate drain system with integral skid-mounted collection reservoir

- BAUER Gas-Tek™ CO monitoring system with calibration kit

- BAUER PLC based controller with 7” color HMI touchscreen display

- NEMA 4 rated electrical enclosure with UL® listed control panel

- Single Phase and Three Phase Electrical Motor Voltage options

- Soft start electronics to reduce the initial start-up load on the truck-mounted generator system

- Compressor low oil pressure and high-temperature safety shutdowns

- Emergency stop push button

- Stainless steel interconnecting piping

SCBA CONTAINMENT FILL STATIONS

- Designed & Tested to meet NFPA 1901 2016 Edition Standards

- BAUER CFS5.5® fill stations were tested and passed a 5500 PSIG SCBA rupture with 110 cu ft cylinder

- Our standard fill stations can be supplied in a single, two, or three position configurations

- Dual two and three position fill stations are popular with larger fire departments

- Can accommodate many sized steel & Aluminum Dive Tanks

- Remote Mounted HMI Compressor Controls are integrated into our fill station control panels

- Top or Side Mounted DUAL Function Cascade Control Panels

- Air selector valve to select filling “From Compressor / Fill From Storage”

- ABS Risers located in each fill position to ensure proper height of SCBA cylinder within Fill Station

- Custom Fill Control Panels to include High Pressure and Low-Pressure Hose Reel Controls

- Air Storage Refill Port

AIR STORAGE SYSTEMS

- 10 Year retest requirement for UN/ISO Cylinders

- ASME coded cylinders rated to 7000 PSIG working pressure (3:1 structural safety factor)

- Safety Relief Valve installed on each ASME Cylinder along with moisture drain valve

- All Cylinders are pre-piped with stainless steel tubing within the compressor skid package

- Cylinders can be shipped loose for custom installation within the truck body

CUSTOM-DESIGNED SYSTEM:

- Up to 7,000 PSIG

- 13 to 35 SCFM (368 to1017 l/min) Charging Rate

- 10 to 30HP (7.5 to 22kw)

- Electric and diesel driven

- UN and ASME air storage cylinders

- Custom airflow control panels

- NFPA 1901 Approved, 3rd Party Tested Containment Fill Stations

- Proven performance with over 35 years of experience