![]()

Need assistance with selecting the correct solution to meet your specific requirements?

![]()

To see the entire Argon Systems Catalog

SOME OF THE MOST COMMON USES OF ARGON

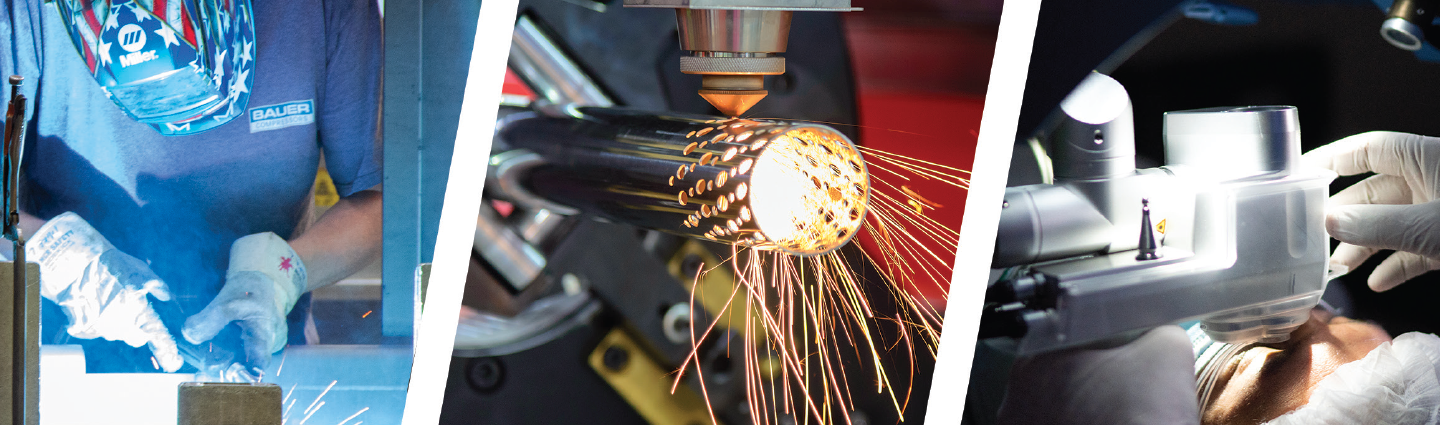

INDUSTRIAL MANUFACTURING:

Argon is perhaps best known for its use as a shielding gas in MIG (metal inert gas) and TIG (tungsten inert gas) welding. Argon prevents contamination of the welding surfaces by displacing air and moisture. It also plays a role in stabilizing and shaping the penetration profile of the arc, which helps to ensure the integrity of the weld, and encourages first-time quality.

Stainless steel requires a carbon content of 1.2% or less. To achieve this, manufacturers employ a process called argon-oxygen decarburization. A mixture of argon and oxygen is injected into liquid steel, and the oxygen removes the carbon by forming carbon monoxide. In contrast, argon gas protects steel from the corrosive effects of oxygen and regulates chromium loss. Chromium makes stainless steel more rigid and more resistant to corrosion.

Inert gas chambers are spaces where atmospheric air is replaced with an inert gas to provide a protective environment. 3D printers often employ inert build chambers and lasers that sinter polymer powder, fine metal dust, or other materials to create inexpensive components. 3D printing, a form of additive manufacturing, consumes fewer resources than traditional manufacturing methods. Once again, argon is the gas of choice when working with metals. It protects the metal powder from moisture and oxygen, whereas other gases could cause the formation of nitrides or other impurities.

Argon can be a blanket gas for growing silicon and germanium crystals. Silicon crystals are commonly found in solar panels and electronics, and germanium crystals are used in fiber optics and light-emitting diodes (LEDs).

HEALTHCARE USES:

When administered in ventilation, argon has cardioprotective and neuroprotective qualities. It can help treat arrhythmias and even protect the brain after experiencing oxygen deprivation.

Argon lasers are extremely precise. They can remove tumors and other abnormal growths, provide retinal phototherapy, and even repair damaged arteries. They can also be used to treat retinal detachment and retinal phototherapy for those who are diabetic.

LIGHTING:

Argon is used to fill fluorescent and incandescent bulbs to protect the filament, prolonging bulb life. Additionally, the inclusion of argon allows light to be generated at much lower voltages.

The noble gases are used to produce varying colors in decorative lighting. While they are all colloquially referred to as “neon lights,” neon produces a red-orange color, helium glows yellow or orange, and argon glows with a blue or violet light.

OTHER USES:

Fully transparent, moisture resistant, and with low thermal conductivity, argon increases the efficiency of double-paned windows. This is very common in Europe, where central air conditioning is less common than in the United States. Windows filled with argon will have two holes along the spacer material. One hole is for pumping argon in, while the other is to allow the displaced air to exit.

Argon can be used as an insulator in scuba drysuits, protecting the wearer from body heat loss. Since argon withstands compression better than atmospheric air, a drysuit utilizing argon can be used at greater depths where more pressure is exerted on the diver.

This is just a handful of some of the most popular uses for argon, whose properties make it so effective that far too many applications employ it to name.