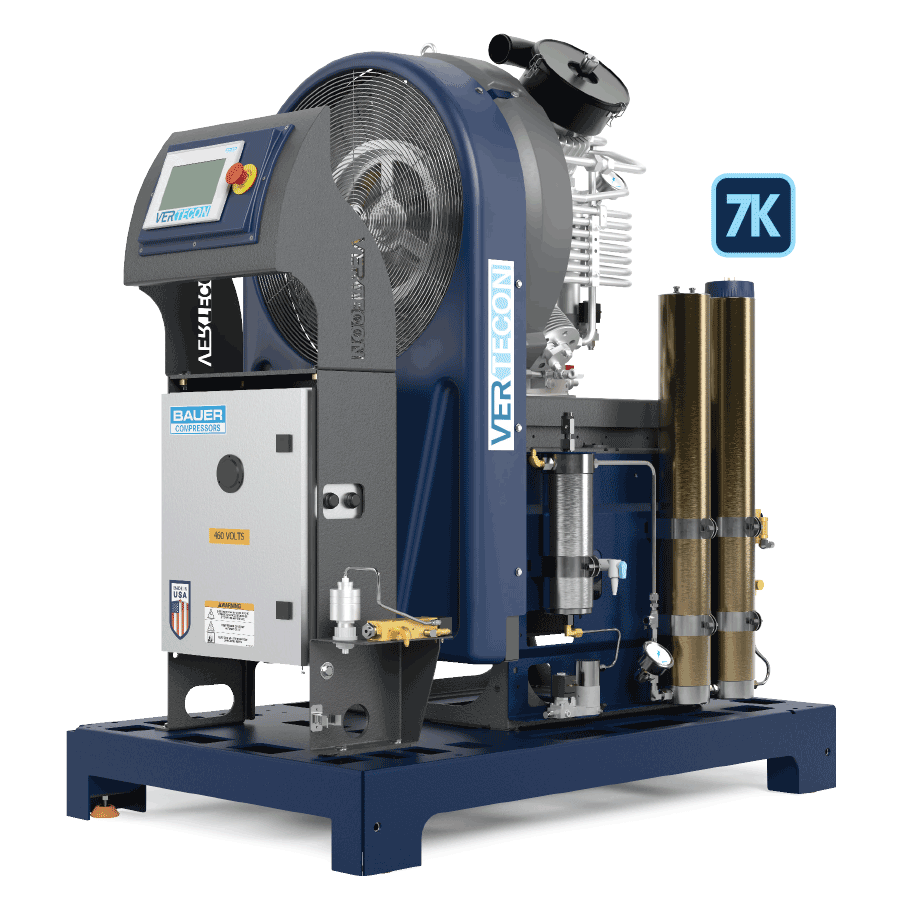

7000 PSIG Breathing Air Systems

As SCBA working pressures increase, so must the fire department’s high-pressure breathing air compressor system. If left unchecked, the Department runs the risk of not supporting their breathing air demand for grade “E” breathing air. BAUER COMPRESSORS, Inc. is the first company in the industry to offer a wide and varied product portfolio to meet your specific needs. We start with a performance-proven BAUER air-cooled high-pressure compressor designed, built, and rated for continuous duty operations at 7000 psig. The compressor has been in existence long before others. It has proven itself since 1992 in the high-pressure, non-breathing air market where up-time demands are far more stringent than the breathing air market. We couple the compressor to one of our BAUER high-pressure breathing air purification systems, designed for continuous operations at 7000 psig while meeting the Compressed Gas Association’s rigorous breathing air quality standards for grade “E” air, and or the National Fire Protection Association (1989 standard for high-pressure breathing air) along with many other recognized global standards.

BAUER COMPRESSORS, Inc. offers two (2) models of 7000 psig compressor package, each outfitted to meet your specific requirements. A simplistic component system utilizing one of our VERTECON® compressor packages. Along with an independently tested and verified CFS5.5®-3S or CFS5.5®-2S SCBA containment fill station and an ASME coded air storage system; Or step up to either a UNICUS® 4S or UNICUS® 4i All-In-One compressor package, each outfitted to meet your specific needs. No matter which compressor system you select, rest assured all of the components were chosen in strict adherence to NFPA 1901-2016 edition, calling for a 4:1 structural safety factor.

![]()

Need assistance with selecting the correct solution to meet your specific requirements?

![]()

To see the entire Breathing Air Brochure